In the world of robotics and autonomous systems, control systems are the unsung heroes. These systems act as the brain that keeps everything running smoothly—constantly reading data from sensors, interpreting that information, and sending precise commands to actuators. Without a robust control system, even the most advanced robot would be nothing more than an expensive pile of wires and metal.

As an electrical engineer who’s spent much of his career working on embedded systems and industrial automation, I’ve watched with excitement (and occasionally frustration) as control systems have grown in complexity and capability. Whether you’re dealing with a robotic arm in a factory or an autonomous drone navigating a forest, control systems make the difference between a functioning solution and a failed prototype.

From Simple Feedback Loops to Adaptive Intelligence

Traditionally, control systems were designed around relatively simple feedback mechanisms—what we call PID (Proportional-Integral-Derivative) controllers. These are still widely used, and for good reason: they’re reliable and effective in many scenarios. But as the systems we build become more dynamic and operate in unpredictable environments, we’ve had to go beyond PID.

Modern robotics often leverages model predictive control (MPC), machine learning-enhanced algorithms, and sensor fusion techniques. These allow robots and autonomous machines to adapt in real time. For instance, a self-driving car needs to process data from LiDAR, cameras, and GPS all at once, making split-second decisions as its environment changes.

This evolution means control systems now need to handle far more than just maintaining a set speed or position—they need to adapt, learn, and sometimes even predict future states.

Real-Time Data is Key

At the heart of these smart control systems is real-time data. I’ve always been fascinated by how tightly coupled software and hardware need to be when milliseconds matter. Whether it’s for balancing a bipedal robot or adjusting torque in an electric drivetrain, latency can’t be an afterthought.

One of the big challenges I often face when designing embedded systems is optimizing the flow of data between sensors, processors, and actuators. You need tight timing, low jitter, and rock-solid reliability. A delay of just a few milliseconds can cause a robotic arm to overshoot or a drone to crash.

That’s why modern control systems are increasingly being designed with dedicated real-time operating systems (RTOS) and specialized hardware such as FPGAs or digital signal processors (DSPs). These tools allow for faster data handling and greater precision in control algorithms.

Safety and Redundancy

Another essential aspect of control systems in autonomous technologies is safety. In industrial settings, a malfunctioning robot can cause injury or damage equipment. In autonomous vehicles, the stakes are even higher.

To mitigate risks, we build in redundancy. That means multiple sensors verifying the same information, fail-safe mechanisms, and software watchdogs that detect and respond to faults. I’ve worked on systems where one microcontroller’s job is solely to monitor the health of the main processor. If it detects a fault, it can shut down the system or switch to backup control logic.

Good design is about anticipating what could go wrong and engineering ways to handle it gracefully. In my experience, the best engineers are not just builders—they’re risk managers.

Integration Challenges

One of the more complex challenges I regularly deal with is integrating control systems into larger platforms. It’s rarely a plug-and-play experience. You have to consider mechanical tolerances, signal interference, power supply noise, and even environmental factors like temperature and vibration.

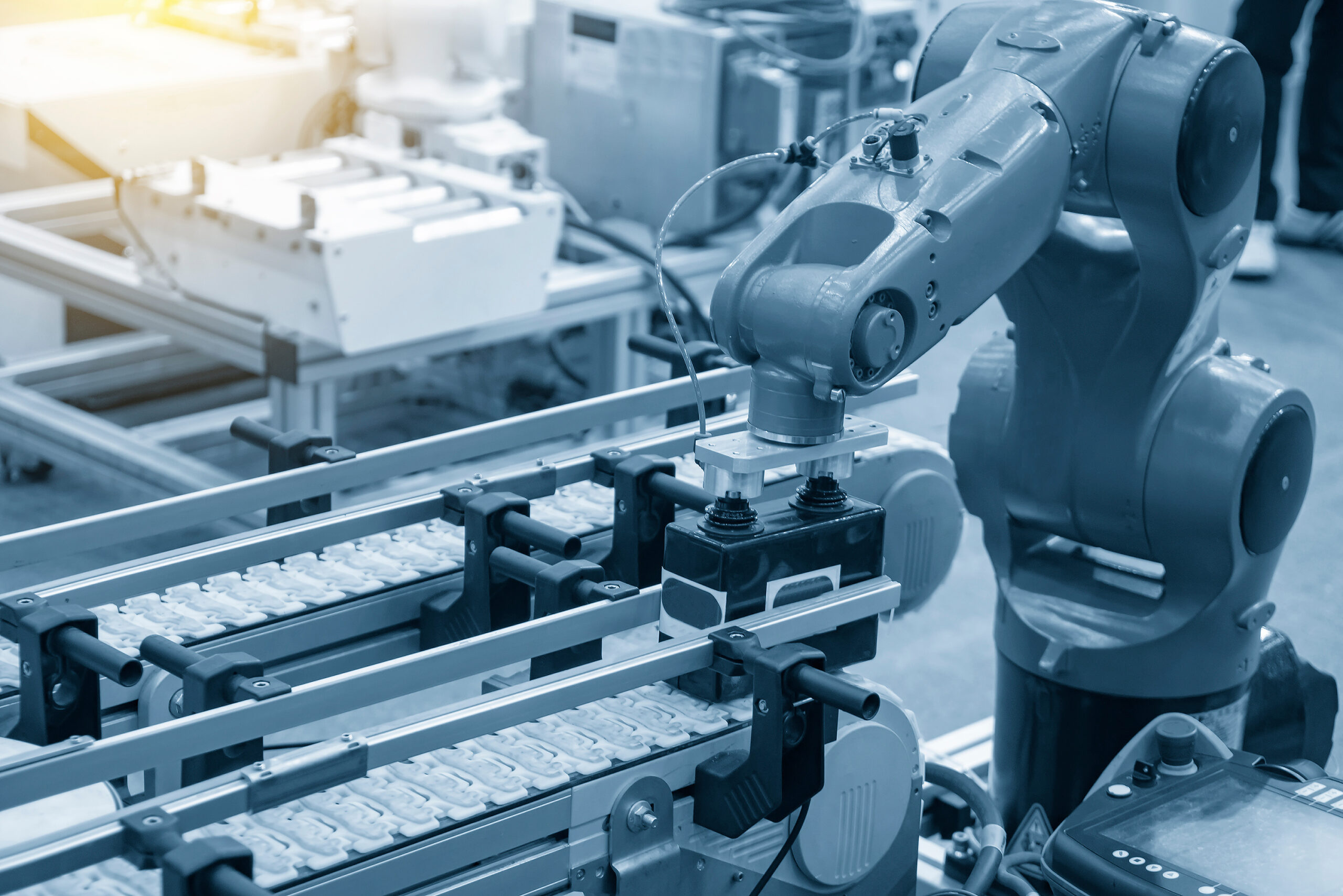

For example, I once helped retrofit a legacy manufacturing line with collaborative robots. The physical integration was tough enough, but the real challenge was ensuring the control system could talk to older PLCs while still responding in real-time to new sensor data. Bridging that gap required a mix of protocol translation, careful timing, and custom firmware.

That project taught me a lot about the importance of modularity and abstraction in system design. When each component is built to handle changes and interact cleanly with others, you can adapt and evolve the system much more easily.

Looking Ahead

We’re only scratching the surface of what’s possible. With the continued rise of edge computing, 5G, and AI co-processors, control systems are poised to become even more powerful and autonomous. I’m particularly excited about developments in neuromorphic computing and biologically inspired algorithms, which could push robotics into new realms of responsiveness and decision-making.

As engineers, our challenge will be to harness this power without making things overly complex or fragile. Simplicity, reliability, and clarity will remain the cornerstones of good control system design—no matter how advanced the tools become.

Final Thoughts

Control systems are where software meets the physical world. It’s a domain that demands rigor, creativity, and a deep respect for timing and physics. For me, it’s one of the most rewarding areas of engineering because you can see your work come to life.

Whether it’s guiding a robotic welder or helping a drone land safely, every successful project is a reminder of how vital control systems are to our modern, automated world. And as we push further into autonomous technologies, their role will only grow.